There are times that the context, the back story of something is so unique it almost overshadows the thing itself. Detroit's Packard plant, which turned out its final vehicle in 1958, was in its time a symbol of Detroit's affluence and energy, stretching along a mile long of East Grand Boulevard beginning in 1903. Internationally recognized architect and Detroit's own Albert Kahn was the architect and designed this factory as the first auto production plant built with reinforced concrete. While the structure itself has been gutted, burned, flooded and stripped, the concrete shell has stood largely intact for over 100 years.

The Packards manufactured there could stand with any marque in the world. Stylish, powerful, and classically large, the affluent frequently purchased their car sans bodywork and had it shipped to any number of builders (LeBaron, Fisher, etc.) for finishing as did other fine cars like Cadillac, Rolls Royce and Duesenberg.

By juggling and redesigning its line-up to survive the Great Depression, which exacted a horrific toll on the people of Detroit, top of the line cars could still be procured at a Packard dealership as well as more mundane but still first quality models like the Light Eight and the 120.

The outbreak of the Second World War brought automobile manufacturing to a halt in America, save for the nimble little Jeep with its production split between Ford Motor Company and Willis Overland Motors.

Other manufacturers were pressed into duty making or assembling all sorts of weaponry.

|

| Making shells at Chevrolet |

Between 1942 and 1945 Chevrolet produced, “60,000 Pratt & Whitney bomber and cargo plane engines; 500,000 trucks; 8 million artillery shells; 3,000 90 mm cannon barrels; 1 million tons of aluminum forgings; 1 million tons of grey iron castings; 2,850 tons of magnesium forgings; and 3,800 T-17 Staghound armored scout cars” according to the Automotive News.

Ford built a limited access road to its new factory in Willow Run, Michigan, a 3.5 million square foot building entirely under one roof. It began operation less than a year after breaking ground and eventually honed its manufacturing technique to roll out a B-24 bomber every 60 minutes.

But this story doesn't begin in Detroit or even at the Rouge plant.

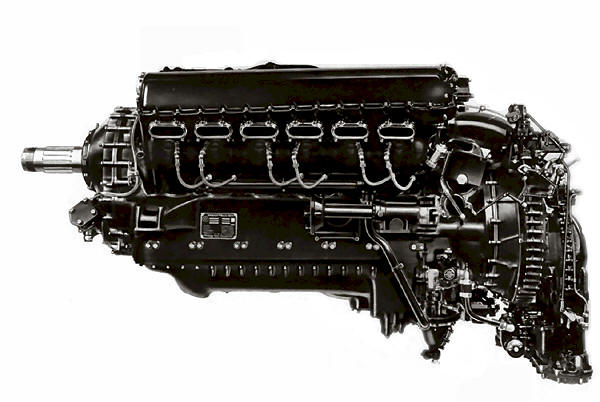

The Merlin airplane engine

was conceived and engineered in England. In the early 1930s Germany

began arming itself and substantially growing its armed services. The

English Air Ministry (the major buyer of Rolls Royce aero engines)

responded by releasing specifications for a new fighter that would be

capable of attaining 310 mph.

In 1932 Sir Henry Royce (yes that Royce) realized the Kestrel airplane engine that Rolls Royce was making was getting a bit out-dated. Royce wanted something based on the Kestrel but bigger and especially faster. Work was begun on the PV (for Private Venture) 12, a 27 litre V-12 with a target horsepower of around 900 hp.

In 1934, the first Merlin was tested, but it only produced 790 hp. Rolls Royce knew the potential of the engine and began refining it in the air, powering a Hawker-Hart biplane. It didn't take long to address some of the first 175 Merlin I's demons: cracked heads and leaking coolant needed immediate attention. To take control of the various problems the engine displayed, Rolls began setting aside just completed random engines and running them at full throttle until they broke. The engine's reputation (and horsepower) began to improve immediately. By 1935, a Merlin III was placed in a Royal Air Force Spitfire and reportedly produced 2,160 hp. Rolls eventually built 33 prototype engines culminating in the 1,035 hp Merlin F.

Rolls-Royce

Merlin III Specifications

Type: inline liquid-cooled internal combustion engine

Configuration: 12-cylinder 60-degree upright vee

Valve train: Overhead camshaft-actuated, two intake and two exhaust valves per cylinder, sodium-cooled exhaust valve stems

Fuel system: Updraft carburettor with automatic mixture control

Oil system: Dry sump with one pressure pump and two scavenge pumps.

Cooling system: Pure ethylene-glycol cooling mixture, unpressurized.

Supercharger: Single-speed, single stage.

Type: inline liquid-cooled internal combustion engine

Configuration: 12-cylinder 60-degree upright vee

Valve train: Overhead camshaft-actuated, two intake and two exhaust valves per cylinder, sodium-cooled exhaust valve stems

Fuel system: Updraft carburettor with automatic mixture control

Oil system: Dry sump with one pressure pump and two scavenge pumps.

Cooling system: Pure ethylene-glycol cooling mixture, unpressurized.

Supercharger: Single-speed, single stage.

-Bore:

5.4 in (137.3 mm)

Stroke: 6 in (152.5mm)

Capacity: 1,648.96 cu in (27.04 l)

Stroke: 6 in (152.5mm)

Capacity: 1,648.96 cu in (27.04 l)

Maximum

power:

1,030 hp at 3,000 rpm at 5,500 ft (1,680 m)

Weight: 1,375 lbs (623,6 kg)

Weight: 1,375 lbs (623,6 kg)

Early testing of the Supermarine Spifire and Hawker Hurricane with the 890 hp Merlin C demonstrated the potential of these match-ups but the engine needed more horsepower.

In 1937, the cylinder heads were redesigned. The intake valve had been canted at a 45 degree angle, but it was found that moving the position directly over the cylinder bore provided an instant improvement. The Merlin II was born with over 1,000 hp. More importantly, Sir Stanley Hooker began modifying the Merlin Supercharger. The engine gave up some of its power when flying at 6,000 ft and below, an altitude that German Messerschmidt thrived at.

|

| Merlin Supercharger |

The first modifications added 22 mph to the planes and gave up nothing at the lower altitudes. Development continued into and through the war years. Eventually boost would increased 33% and eventually a second supercharger was added.

Another problem was its need for frequent maintenance; the turnaround between rebuilds was just 250 hours of flight. Other airplane power plants could easily go 1,000 hours plus between rebuilds.

But pilots loved the big

brutes and the Merlin's adoption was across a number of platforms: "The

Mark II and Mark III engines generated 1,030 hp. The Mark XII was

used in Spitfires Mark II’s and generated 1,150 hp. The Mark II

Hurricane used the Merlin XX and generated 1,480 hp. The Spitfire

Mark V – the most widely produced variant – used the Merlin 45,

which generated 1,515 hp".

The U.S. also needed an engine for its P-51 Mustang fighters and eventually selected the Merlin. But the three English factories producing the engine were already working around the clock. The search for an American manufacturer began. After first asking for consideration, then recanting, Henry Ford bowed out of the search, although Ford of Great Britain eventually produced 36,000 Merlins.

Rolls Royce then turned to Packard Motors, a manufacturer of very similar automobiles as Rolls Royce. With automobile production halted, Packard moved Merlin production into its North building.

Packard Merlin engine assembly.

But the transformation wasn't an easy one. There were over 14,000 parts that needed to be fitted on each engine. Rolls Royce assembled Merlins in teams that each worked on a single engine through completion. This method was slow and was laborious, filing a bit there, bending a bit here.

Packard needed assembly-line-ready parts and, working with Rolls, reduced the tolerances for nearly every one of those 14,000 parts.

To ensure parts comparability across all of the engines, Packard needed to use imperial sized tools and parts rather than SAE which was the norm stateside. Any modification to the engine had to be submitted and approved by Rolls Royce and Packard found a number of available parts superior to the original Rolls parts, not least of which was crankshaft bearings.

American aircraft manufacturers had learned that bearings made of a silver/lead alloy and coated with indium were more corrosion resistant and offered superior wear. Captured planes dissected by German engineers who studied these bearings assumed the indium was simply an impurity in the alloy. Not only crankshaft bearings but also American made carburetors, magnetos, spark plugs, etc. were adopted by Rolls, each manufactured to Rolls Royce specifications.

The first Packard built

Merlin engine rolled off the line in 1941. The early engines

displayed some problems but these were quickly worked out by

engineering teams comprised of technicians from both sides of the

Atlantic.

RAF P-51-A

|

| Merlin fighters escorting B-29 |

In total, Packard produced about a third of the total run of Merlins. Most of the American made Merlins went not to Spitfires and Hawkers but into the P-51 Mustang which had been limited above roughly three miles by its Allison V-1710 engine. The Allison was a fantastic engine with fewer than half the parts of the Merlin and even claimed four times the hours flown between rebuilds than the Merlin. Had the Army Air Corps not specified that the Allison needed to be turbo-charged instead of supercharged it may have remained the P-51 engine of choice.

Some of the Packard Merlins were shipped to Great Britain and used in the four engined Lancaster bomber. Early in the war a Lancaster had an engine hit by German fire but returned safely to England with its three remaining Merlins roaring. The Merlin became an instant legend to the RAF pilots.

Lancaster bomber